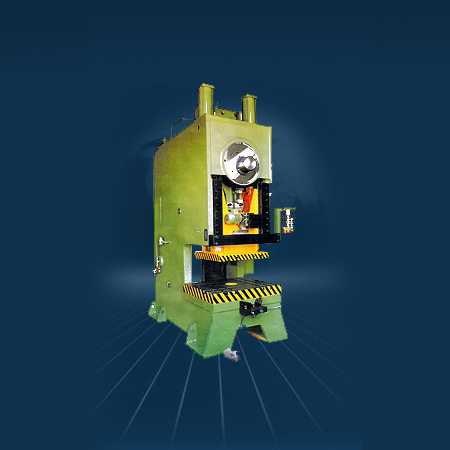

Cross Shaft Power Press

We provide Cross Shaft Power Press with lot more traits. Such power press lessens noise and vibrations and contains minimal frame gapping with low angular deflection. The machine boasts of high rigidity frame and bolster and contains high precision forming for longer die life. This Cross Shaft Power Press is hi-torque pneumatically operated and takes in single disc combined clutch & brake unit. Its gear transmission runs in oil bath and comprises wide slide and bolster area.

Slide Counter Balance : Pneumatic counter balancers are provided to counter the weight of the slide and toolings, which help in taking up the bearing clearances and ease side adjustment, as well as smooth movement of the slide and effective braking.

Pneumatic Clutch- Brake : The single-disc clutch has the advantages like; a continuous joint-free stroke, no adjustment is needed to correct wear on the facings, it is self-ventilating which increases it performance, its operation is safe and fast, etc.

Frame : It is composed by thick steel sheets cut by sinking welded and stress-relived before machining, so as to eliminate any residual tensions. The dimensions study is carried out according to methods of calculations in order to assure the maximum strength against any deformation even under the highest rated load.

Drive : Fully enclosed, well-designed, single-geared, with main shafts supported at three bearing points located close to each other impart sturdiness and eliminate cantilever action. Precision cut, fully enclosed gears running in oil bath with fly wheel and back shaft running in anti friction bearings provide silent and vibration-free operation.

Non geared also available upto 100T

Eccentric Shaft : It is obtained from a forged piece of carbon steel. Prior to the machining, the shaft undergoes an ultra-sound inspection and a chemical and metallographic test, Shaft is ground finished on Bearing surfaces, all main Bearings are of Heavy Walled Nickel phosphorous Bronze, which are hand scrapped.

Electrical Controls : A lockable selector switch of ONCE, INCH and CONTINUOUS mode of operation is provided. The press is equipped with a highly reliable Dual Solenoid Valve, which prevents faulty operation by electrical lockout. ‘Top Stop’ to stop the press at Top Dead Centre. Two Hand Engagement Device, Emergency Stop’ are some of the other standard features. The electric equipment is in line with the latest safety.

Quality

- Reduce noise and vibrations.

- Minimal frame gapping, low angular deflection.

- High rigidity frame and bolster.

- High precision forming for longer die life.

- Hi-torque pneumatically operated

- Single disc combined clucth & brake unit

- Gear transmission runs in oil bath.

- Gear transmission runs in oil bath.

Specifications

| Model – LM | 25 | 32 | 40 | 63 | 100 | 160 | 200 | 250 | 315 | 400 | |||||||

| A | B | A | B | A | B | A | B | A | B | A | A | A | A | A | |||

| Force | KN | 250 | 320 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 4000 | ||||||

| Rated distance before B.D.C. | MM | 3.5 | 2.2 | 3.5 2.2 | 4 2.2 | 5 2.5 | 5 2.5 | 6.3 | 6.3 | 6.3 | 8 | 12 | |||||

| Number of slide strokes | SPM | 70 | 140 | 70 140 | 65 130 | 60 120 | 45 100 | 40 | 40 | 35 | 35 | ||||||

| Fly Wheel energy | KJ | 4.4 | 3.0 | 4.4 3.0 | 8.0 4.6 | 16.75 7.8 | 25.0 12.5 | 55.0 | 70.0 | 80.0 | 120.0 | 240.0 | |||||

| Stroke fxed | MM | 80 | 80 | 88 | 100 | 125 | 160 | 200 | 200 | 200 | 250 | ||||||

| Variable stroke (Optional) | MM | 8 -80 | 8-80 | 8-88 | 8-100 | 8-125 | 8-160 | 20-160 | 20-160 | 20-160 | – | ||||||

| Shut height (Stroke down , Adj. up) |

MM | 300 | 300 | 315 | 350 | 450 | 500 | 560 | 560 | 630 | 700 | ||||||

| Slide adjustment | MM | 63 | 63 | 70 | 70 | 80 | 125 | 125 | 125 | 125 | 125 | ||||||

| Bolster area (L-RxF-B) | MM | 630 X400 | 630 X 400 | 800 X 450 | 900 x 550 | 1000×630 | 1120×750 | 1250×800 | 1250×800 | 1450×900 | 1450×900 | ||||||

| Clear distance between uprights | MM | 420 | 420 | 500 | 590 | 670 | 775 | 900 | … | ||||||||

| Main motor | KW x RPM | 2.2×1500 2.2×1000 | 2.2×1500 2.2×1000 | 3.7×1500 3.7×1000 | 5.5×1500 5.5×1000 | 7.5×1500 7.5×1000 | 15×1500 | 15×1500 | 18.5×1500 | 22×1500 | 30×1500 | ||||||

| Slide adjustment motor | KW x RPM | 1.1×1500 | 1.1×1500 | 1.5×1000 | 1.5×1000 | 2.2×1000 | |||||||||||

| Height from floor to Top of bolster |

MM | 800 | 800 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | ||||||

| Required air pressure ATM | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | |||||||

| Die cushion model | DC -72 | DC -72 | DDC – 82 | DDC -102 | DDC – 123 | 3DC – 144 | 3DC-144 | 3DC-164 | DC – 002 – | 30-125 | |||||||

| DIE CUSHION | force | KN | 17 | 17 | 44 | 70 | 100 | 200 | 200 | 270 | 300 | ||||||

| stroke length | MM | 50 | 50 | 50 | 50 | 50 | .75 | 100 | 100 | 100 | |||||||

| pressure pad area | MM | 290 x 200 | 290 x 200 | 335 X 230 | 380 x 260 | 475 X 330 | 535×425 | 600×425 | 600×475 | 850 x 520 | |||||||

| required air pressure | ATM | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 5 | |||||||